10 Essential Tips for Using EZ Scaffold Crank Up Safely and Effectively

Using the EZ Scaffold Crank Up safely and effectively is crucial in construction and maintenance tasks. Scaffolding accidents account for nearly 10% of all fatalities in the construction industry, according to OSHA. This statistic highlights the need for proper use and safety practices. The EZ Scaffold Crank Up is designed to improve accessibility while ensuring stability. However, users must be aware of its limitations.

Safety studies recommend regular inspections of scaffolding equipment. Many professionals overlook this, increasing risks on-site. Effective training for all users is essential to mitigate these risks. Familiarity with the EZ Scaffold Crank Up can make a significant difference. Yet, inadequate knowledge or improper techniques can lead to injuries.

Understanding how to use the EZ Scaffold Crank Up correctly can prevent accidents. Consider that many incidents stem from user negligence. Therefore, implementing best practices will enhance safety in construction environments. Emphasizing vigilance and thorough training will pave the way for safer operations.

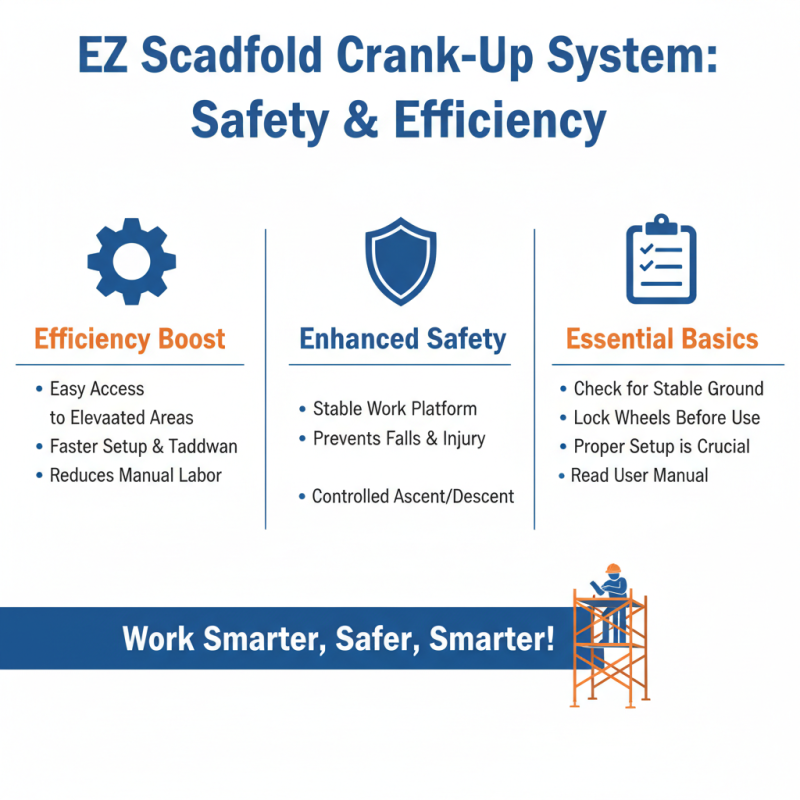

Understanding the Basics of EZ Scaffold Crank Up Systems

Using an EZ scaffold crank up system can significantly enhance safety and efficiency on job sites. These systems allow workers to reach elevated areas with ease. However, understanding the basics is essential before getting started. Knowing how to set up the scaffold properly is crucial. Always check for stable ground before positioning the crank up. Make sure the wheels are locked in place. This prevents unexpected movement during use.

The crank mechanism itself requires attention. It's important to operate it slowly and steadily. Rushing can lead to accidents or equipment failure. Regular inspections of cables and pulleys are necessary. Look for wear and tear that might compromise safety. Workers should also be trained in using these systems. Without proper training, misuse is a risk. Remember, even experienced workers can overlook crucial steps. It's a good idea to review safety protocols regularly.

When working at height, consistency is key. Always wear appropriate safety gear. A harness can be a lifesaver in the case of a fall. Remind team members to stay alert and communicate effectively. Distractions can lead to mistakes. Believe it or not, a simple conversation could divert attention at a critical moment. Encouraging a culture of safety and mindfulness is beneficial. Each team member has a role in ensuring a safe work environment.

Essential Safety Gear for Using EZ Scaffold Crank Ups

When using EZ Scaffold crank ups, safety gear is crucial. The right equipment can prevent injuries. According to industry reports, 30% of construction site injuries are due to falls. Proper safety gear significantly reduces this risk.

Essential gear includes helmets, non-slip footwear, and harnesses. Helmets protect against falling objects. Non-slip boots provide grip on ladders and scaffold surfaces. Harnesses are vital when working at heights. A report from the Occupational Safety and Health Administration states that wearing a harness reduces fall-related injuries by 50%.

Unexpected situations often arise on-site. Workers should regularly inspect their gear. Frayed straps or hard hats with cracks can fail when needed most. Staying vigilant about safety gear can make a difference. Investing in quality gear is not an option; it is a necessity. Protecting yourself means you can focus on the job at hand.

10 Essential Tips for Using EZ Scaffold Crank Up Safely and Effectively

This chart displays the frequency of essential safety tips when using EZ Scaffold Crank Ups based on user compliance surveys.

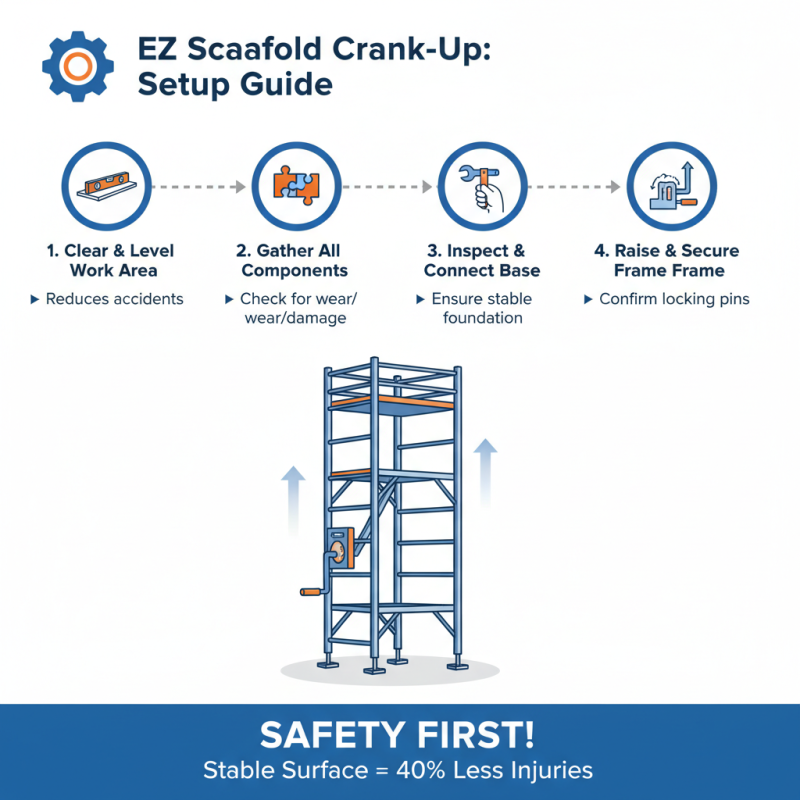

Step-by-Step Setup Process for EZ Scaffold Crank Up

Setting up an EZ Scaffold Crank Up requires careful attention to detail. Begin by ensuring your work area is clear and level. This minimizes the risk of accidents. According to industry standards, a stable surface reduces scaffold-related injuries by up to 40%. Gather all necessary components before starting. Ensure all pieces are in good condition. Check for signs of wear or damage.

As you begin assembly, follow the step-by-step instructions meticulously. Position the crank on stable ground. Connect the scaffold sections securely. Avoid overreaching while assembling. This can lead to falls. A report from the Occupational Safety and Health Administration (OSHA) states that improper setup contributes to 33% of scaffold-related injuries.

Remember that improper height adjustments can be detrimental. Ensure that the scaffold is not extended beyond recommended height limits. Regularly inspect the crank mechanism for smooth operation. A malfunctioning crank can cause unplanned drops. Stay vigilant and maintain a good communication channel with team members during the process. Safety must remain a priority at all times.

Best Practices for Operating EZ Scaffold Crank Ups

Using EZ Scaffold crank ups can enhance safety and efficiency on job sites. However, proper operation is vital. According to the Occupational Safety and Health Administration (OSHA), falls are among the leading causes of workplace injuries, emphasizing the need for careful practices.

One effective tip is to ensure all components are inspected before use. Crank mechanisms should be free of debris. Regular maintenance can prevent malfunctions. A study by the American National Standards Institute (ANSI) revealed that nearly 40% of scaffold-related incidents resulted from equipment failure. Taking care of your equipment is crucial.

Another important practice is to establish a proper setup area. The ground must be level and stable. Avoid placing the scaffold on soft soil or uneven surfaces. Poor setups can lead to tipping. Monitoring weather conditions is equally important. Wind can significantly affect stability, especially on higher platforms. Stay aware of your surroundings and be prepared to adapt. Proper training and awareness can significantly reduce risks associated with using crank up scaffolds.

Maintenance and Inspection Tips for EZ Scaffold Crank Ups

When using EZ scaffold crank ups, regular maintenance is crucial. Inspect the crank mechanism frequently. Look for wear and tear. Cables should be intact, and pulleys should spin freely. If you notice any issues, address them immediately to prevent accidents. It’s easy to overlook these details, but they can make a huge difference in safety.

Checking the scaffolding’s stability is essential. Ensure all legs are adjusted correctly and are on solid ground. A slight misalignment can cause the scaffold to wobble. Pay attention when adjusting the height; uneven lifting can lead to tipping. Always have a team member double-check these adjustments.

After use, store the scaffold properly. Clean any debris from the surface. Moisture can lead to rust, so dry it if it's wet. Use a cover if possible. Reflect on your inspection and maintenance routine regularly. Are you doing everything you can to ensure safety? Consistently evaluate your processes for any gaps.

10 Essential Tips for Using EZ Scaffold Crank Up Safely and Effectively

| Tip | Description | Frequency |

|---|---|---|

| Inspect for Damage | Check for any visible defects or damages before use. | Before each use |

| Check Connections | Ensure all connections are secure and locked in place. | Daily |

| Level the Base | Ensure the ground is stable and the scaffold is level. | Before setup |

| Use Guardrails | Install guardrails on all open sides of the scaffold. | Throughout usage |

| Weight Capacity | Do not exceed the maximum weight capacity specified. | Always |

| Maintain Clear Work Area | Keep the area under the scaffold clear of debris and personnel. | Constantly |

| Proper Ladder Use | Use designated ladders for access, not the scaffold frame. | Always |

| Check for Electrical Hazards | Avoid setting up near power lines or electrical sources. | Before setup |

| Weather Considerations | Avoid using the scaffold in severe weather conditions. | Before each use |

| Regular Maintenance | Schedule periodic maintenance checks for wear and tear. | Monthly |

Related Posts

-

Top 5 Benefits of Using EZ Scaffold Mast Climbers for Your Next Project

-

The Ultimate Guide to Workhorse Scaffolding for Your Construction Projects

-

How to Crank Up Scaffolding for Your Construction Projects Efficiently

-

Understanding Nonstop Scaffolding: Benefits and Applications for 2025

-

How to Find the Best EZ Scaffold for Sale Online?

-

2026 How to Use a Non Stop Scaffolding Manual Effectively?