2026 How to Use a Non Stop Scaffolding Manual Effectively?

In the world of construction, effective scaffolding practices are vital for safety and efficiency. The "non stop scaffolding manual" serves as an essential guide for professionals. John Anderson, an industry leader in scaffolding, once stated, "Understanding the manual is key to working safely and efficiently." This highlights the importance of familiarity with the manual.

Utilizing the "non stop scaffolding manual" effectively requires both practical and theoretical knowledge. Workers must not only read the manual but also apply its principles on-site. It's crucial to understand the various sections that explain different types of scaffold systems. However, despite the manual's thoroughness, confusion can still arise when dealing with unique site challenges.

Industry professionals often find themselves grappling with the manual. Some sections may seem complex or overly technical. It is essential to seek guidance when in doubt. Reflection on past experiences can provide invaluable insights. Embracing the manual fully can lead to improved safety standards and productivity.

Understanding the Non Stop Scaffolding Manual Structure

Understanding the structure of a Non Stop Scaffolding Manual is essential for effective use. Typically, these manuals consist of well-defined sections. Each section covers specific aspects of scaffolding. Clear headers guide you through the information. Bullet points often highlight key points.

Tips: Always note how each section interrelates. This will enhance your grasp of the overall manual.

You may find some terminology challenging. If you're unsure, take a moment to reflect. Understanding why terms are used can deepen your comprehension. Sometimes, the examples provided may feel inadequate. Don't hesitate to experiment with your interpretations.

Tips: Keep a dictionary nearby. It helps in breaking down complex terms. Engaging with peers can also clarify difficult sections. Don't rush the process. Take your time to absorb the content fully.

2026 Non Stop Scaffolding Manual Usage Statistics

Key Components of the Non Stop Scaffolding Manual

Using a Non Stop Scaffolding Manual effectively requires understanding its key components. This manual serves as a detailed guide for managing scaffolding processes smoothly. It typically includes instructions, safety protocols, and best practices.

Safety is paramount. Always prioritize safety measures outlined in the manual. Familiarize yourself with the equipment. Knowing how to set up and dismantle scaffolding is crucial. It minimizes risks and ensures a safe working environment.

Documentation is another important aspect. The manual provides templates for reporting issues or incidents. Use these templates diligently. This creates a paper trail that helps in future assessments. Moreover, engage with the manual regularly. Routine checks will reveal areas needing improvement.

It’s also useful to involve the team in discussions about the manual. Their input can identify gaps in understanding. Encourage questions. This will foster a culture of continuous learning.

When using the manual, don't rush through it. Take your time to comprehend each section fully. Rushed reading often leads to mistakes. Reflect on the processes you implement. Consider what works well and what could be improved. This ongoing evaluation helps build a safer and more efficient scaffolding system.

Step-by-Step Guide to Implementing the Manual

The 2026 Non Stop Scaffolding Manual serves as a vital resource for constructing safe and efficient scaffolding. To implement it effectively, start with understanding the manual's structure. This includes familiarizing yourself with safety guidelines, materials, and calculations required for your projects. Research indicates that nearly 30% of scaffolding accidents arise from improper handling and setup. Understanding and adhering to these guidelines can significantly reduce risks.

Next, move to practical application. Create a checklist derived from the manual, tailoring it to your specific project. Regularly consult this checklist during assembly to ensure compliance with safety standards. A 2022 industry report revealed that job sites utilizing comprehensive checklists improved their safety compliance by over 40%. Visual aids from the manual can assist workers in understanding complex assembly instructions quickly.

Incorporating safety training sessions is crucial. A recent study highlighted that 55% of workers felt unprepared after a brief training period. Continuous education on the manual's details fosters an environment of preparedness. Encourage workers to reflect on their experiences with scaffolding. Discussions can unearth common pitfalls, leading to better practices. The manual is not just a guide; it's a foundation for safer work environments.

2026 How to Use a Non Stop Scaffolding Manual Effectively? - Step-by-Step Guide to Implementing the Manual

| Step Number | Description | Estimated Time (Hours) | Required Materials | Notes |

|---|---|---|---|---|

| 1 | Review the manual and understand the objectives | 2 | Non-stop scaffolding manual | Familiarize yourself with key terms and processes |

| 2 | Gather necessary equipment and materials | 3 | Scaffolding materials, safety gear | Ensure all equipment meets safety standards |

| 3 | Set up scaffolding according to the manual | 4 | Tools for assembly | Follow steps closely for safety |

| 4 | Inspect the structure for stability | 1 | Safety inspection checklist | Check load capacity and bolts |

| 5 | Begin work on project | Ongoing | Tools and materials specific to project | Ensure team follows safety protocols |

| 6 | Complete the project and disassemble scaffolding | 3 | Disassembly tools | Carefully remove all scaffolding components |

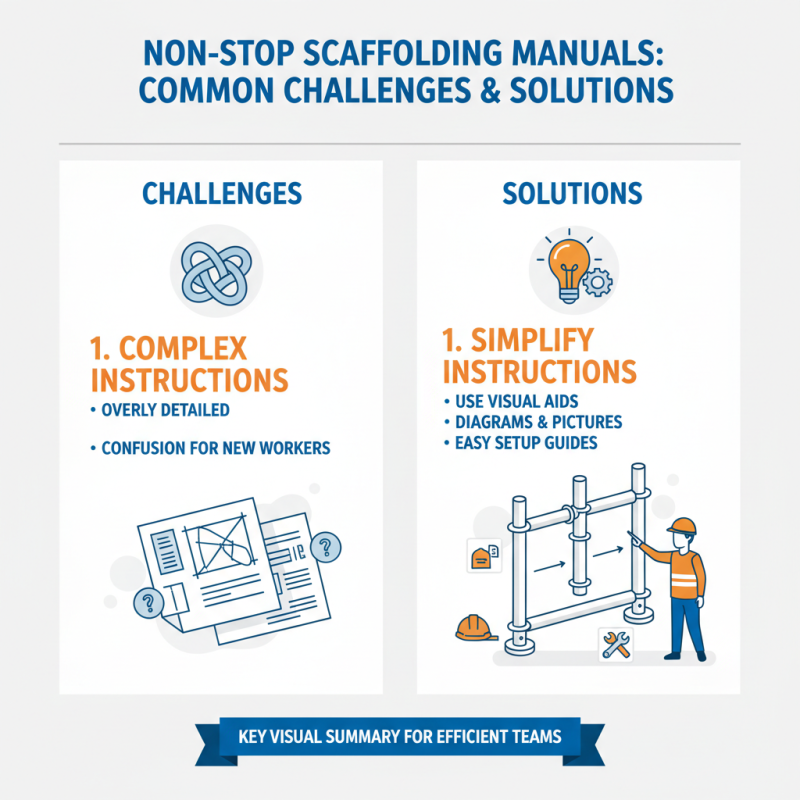

Common Challenges and Solutions in Using the Manual

Using a non-stop scaffolding manual can be an effective approach for many construction teams. However, there are common challenges. One such challenge is the complexity of instructions. Sometimes, the manual is overly detailed. This can confuse workers, particularly those who are new. It is beneficial to simplify the instructions. Visual aids can help too. Diagrams or pictures can illustrate proper setup.

Another issue is the lack of communication among team members. When using a manual, not all workers may be on the same page. This can lead to mistakes or unsafe practices. Regular briefings can enhance understanding. A few minutes daily to discuss plans can make a big difference. Encourage team members to share their thoughts. Open dialogues often reveal hidden challenges.

Lastly, adapting to the manual can take time. Teams may feel pressure to complete tasks quickly. Rushing can lead to errors. It is essential to encourage patience. Building proficiency with the manual often requires practice. Small, incremental improvements are more effective than rushing to finish a project. Create an environment where learning is valued, even if it means facing some setbacks along the way.

Best Practices for Maintaining Scaffolding Efficiency

Maintaining scaffolding efficiency requires attention to detail and proper practices. Regular inspections are crucial. A visual check can reveal potential safety hazards. Missing components or wear can occur without notice. Addressing these issues early can prevent costly delays and accidents.

Training workers is also essential. Ensure they understand the scaffolding manual. Poorly trained staff may set up scaffolds incorrectly. This can lead to instability. It’s vital to foster a culture of accountability among workers. They should feel empowered to report concerns.

Another factor is the organization of workspace. A cluttered area can hinder access to scaffolding components. Keeping tools and materials well-organized promotes efficiency. Occasionally, it's challenging to maintain this order amidst busy projects. Reflection on daily practices can help identify improvement areas. Consider ways to enhance workflows without sacrificing safety.

Related Posts

-

The Ultimate Guide to Workhorse Scaffolding for Your Construction Projects

-

Understanding Nonstop Scaffolding: Benefits and Applications for 2025

-

Top 5 Benefits of Using EZ Scaffold Mast Climbers for Your Next Project

-

Discover the Best Crank Up Scaffolding for Sale: Top Models of 2025

-

How to Effectively Use Non Stop Crank Up Scaffolding for Your Construction Projects

-

Why You Should Consider Buying EZ Scaffold for Sale Today