Understanding Nonstop Scaffolding: Benefits and Applications for 2025

As we approach 2025, construction methods continue to evolve. One innovation gaining traction is the nonstop scaffold. This system enhances safety and efficiency at construction sites. Traditional scaffolding often disrupts workflow. In contrast, the nonstop scaffold allows seamless access to work areas.

The benefits are significant. Workers can operate without frequent interruptions. This leads to improved productivity. Additionally, the nonstop scaffold minimizes the risk of accidents. Safety features are integrated into the design. However, challenges remain in adapting to this new approach. Training for workers is crucial. Understanding how to utilize this scaffold effectively is key.

Despite its advantages, the nonstop scaffold may not be suitable for every project. Some structures require more traditional methods. Reflecting on these limitations is essential. Careful consideration is needed when implementing this innovative system. The construction industry must balance progress with practicality.

Understanding the Concept of Nonstop Scaffolding in Construction

Nonstop scaffolding is revolutionizing construction methods. This concept promotes continuous and uninterrupted workflow on multiple projects. In 2025, it's expected that the adoption of nonstop scaffolding will improve efficiency by at least 30%. Traditional scaffolding can cause delays. Weather, installation time, and careful planning often hinder progress.

The benefits extend beyond speed. Safety is a major concern in construction, and nonstop scaffolding enhances worker safety. A report from the Occupational Safety and Health Administration (OSHA) shows that scaffolding-related accidents account for about 60% of construction injuries. Nonstop systems minimize the risk of falls. They provide stable platforms and reduce the number of setup changes.

However, there are challenges. Implementing nonstop scaffolding requires careful design and planning. Not all structures are suitable. Site conditions may limit options. Additionally, workers must be trained adequately. Misunderstandings can lead to mistakes. Effective communication is vital to mitigate these issues. While potential benefits are significant, it's crucial to address these concerns. Investing in continuous training might yield better results in safety and efficiency.

Key Benefits of Nonstop Scaffolding for Construction Efficiency

Nonstop scaffolding is revolutionizing construction efficiency. This innovative approach allows workers to access higher elevations without frequent adjustments or interruptions. According to industry reports, projects using nonstop scaffolding can reduce downtime by up to 30%. This enhances productivity while also improving safety for the crew.

Tips for implementation: Always ensure proper training for the workforce. Misuse can lead to accidents and delays. Regularly inspect scaffolding systems to maintain integrity and compliance with safety standards. These steps are essential in preventing costly mishaps.

Moreover, nonstop scaffolding promotes better workflow management. Workers can shift seamlessly from one task to another. A report from the Construction Industry Institute noted that streamlined processes can lead to a 15% increase in overall project completion speed. However, it is crucial to evaluate the initial setup costs versus the long-term benefits. Some teams may face challenges with adapting to new protocols. Creating a tailored approach is vital.

Understanding Nonstop Scaffolding: Benefits and Applications for 2025

| Benefit | Description | Application Context | Efficiency Improvement (%) |

|---|---|---|---|

| Increased Safety | Minimized falls and accidents through robust design. | High-rise buildings and construction sites. | 30 |

| Enhanced Speed | Quick assembly and disassembly reduce project timelines. | Commercial and residential construction. | 25 |

| Cost-Effectiveness | Reduces labor costs and rental expenses. | Large-scale infrastructure projects. | 20 |

| Adaptability | Can be easily modified for different project needs. | Renovation and expansions. | 15 |

| Quality Control | Greater control over construction quality and timelines. | Complex and detail-oriented projects. | 18 |

Applications of Nonstop Scaffolding in Major Industries for 2025

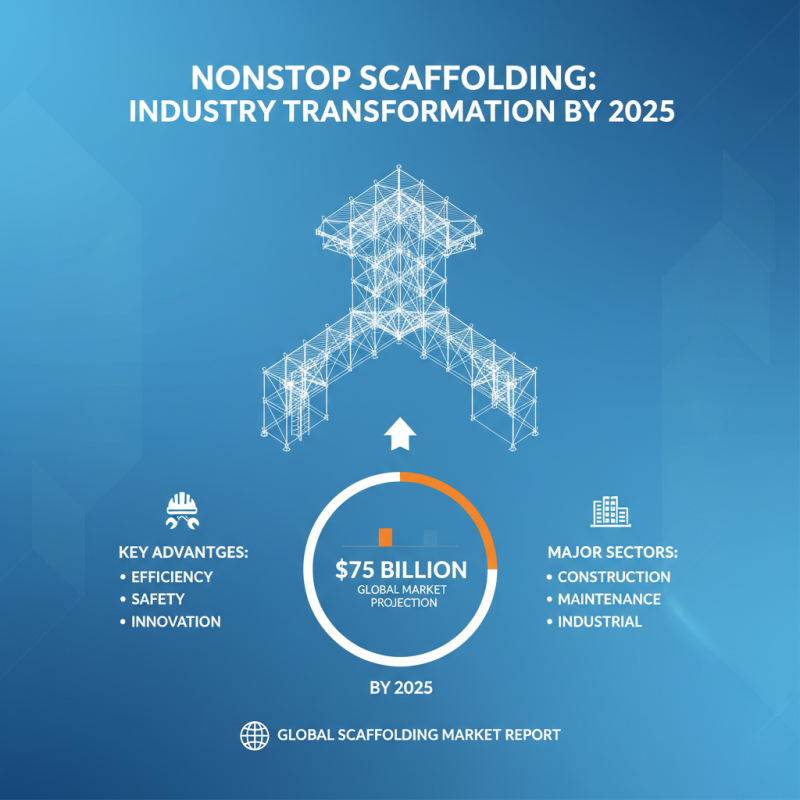

Nonstop scaffolding is transforming various industries as we approach 2025. This innovative construction solution offers significant advantages, especially in sectors like construction and maintenance. According to the Global Scaffolding Market Report, the market is projected to reach $75 billion by 2025. This rapid growth reflects an increasing demand for efficient and safe work environments.

In construction, nonstop scaffolding enhances productivity. Workers can access elevated areas without delays. A recent study noted that projects using nonstop scaffolding reduced completion times by 20%. It is crucial for builders to understand how to integrate these systems effectively. Mistakes in setup can lead to safety hazards. Safety training is essential; however, not all workers receive adequate preparation.

Moreover, industries like oil and gas are embracing nonstop scaffolding to facilitate maintenance cycles. This approach allows for quick repairs and inspections while minimizing downtime. Some reports indicate that downtime costs companies millions annually. Addressing these challenges and finding reliable solutions will be vital for future operations. As we progress into 2025, the potential for nonstop scaffolding in these fields is clear, yet the execution raises questions that companies need to answer.

Comparative Analysis: Nonstop Scaffolding vs. Traditional Scaffolding Systems

Nonstop scaffolding represents an evolution in construction techniques. Unlike traditional scaffolding, it allows for uninterrupted work on-site. This innovation leads to heightened efficiency. Projects can progress quickly, minimizing delays. Reduced setup and dismantle times benefit construction schedules significantly.

However, challenges exist. Not all projects benefit equally from nonstop scaffolding. For larger structures, traditional scaffolding may still be preferable. Workers may find it harder to navigate in nonstop setups. Safety concerns can arise if not implemented correctly. Each project requires careful consideration of scaffolding types.

In terms of cost, nonstop systems can be beneficial in the long run. They often reduce labor hours and increase productivity. Traditional systems may have lower initial costs but can lead to budget overruns due to delays. This presents a challenge for project managers who must weigh options carefully. Overall, understanding the nuances of these systems is crucial for successful project execution.

Future Trends and Innovations in Nonstop Scaffolding Technologies

The landscape of nonstop scaffolding technologies is rapidly evolving. In 2025, new trends will reshape how projects are constructed. One innovation is modular designs that allow quick assembly and disassembly. These systems reduce construction time significantly. Workers can focus on tasks rather than dealing with cumbersome setups. Flexibility in adapting to various project sizes is also a key benefit.

Another trend involves smart technology integration. Sensors can monitor structural integrity and worker safety. This real-time feedback improves efficiency and reduces risks. However, such advancements raise questions about data privacy and cybersecurity. Workers must be trained to navigate these technologies effectively. As we embrace change, we should reflect on the balance between innovation and safety.

There's a growing emphasis on sustainability in scaffolding practices. Eco-friendly materials are gaining popularity. They not only help the environment but also meet regulatory standards. Yet, the initial costs for greener options can be high. Companies need to consider long-term benefits alongside immediate expenditures. Innovation comes with challenges, and navigating these will be crucial for success in the evolving landscape of nonstop scaffolding.

Related Posts

-

How to Crank Up Scaffolding for Your Construction Projects Efficiently

-

Essential Tips for Choosing the Right Crank Scaffold for Your Project

-

Top 5 Benefits of Using EZ Scaffold Mast Climbers for Your Next Project

-

Discover the Best Crank Up Scaffolding for Sale: Top Models of 2025

-

The Ultimate Guide to Workhorse Scaffolding for Your Construction Projects

-

Why You Should Consider Buying EZ Scaffold for Sale Today