The Ultimate Guide to Workhorse Scaffolding for Your Construction Projects

In the realm of construction, choosing the right scaffolding system is crucial for ensuring safety, efficiency, and productivity on the job site. "Workhorse scaffolding" has emerged as a reliable and indispensable solution for contractors seeking to streamline their projects. Industry expert James Madison, a seasoned scaffolding consultant with over two decades of experience, emphasizes the significance of this type of scaffolding by stating, "Workhorse scaffolding is not just about support; it transforms the way we approach construction tasks, making projects safer and more efficient."

With its robust design and adaptability, workhorse scaffolding serves as a backbone for various construction activities—from residential buildings to large-scale commercial projects. The durable framework and easy assembly of these systems allow workers to access heights safely while maintaining the integrity of the work environment. As challenges in construction continue to evolve, staying informed about the best practices and innovations in scaffolding can make a significant difference. This guide delves into all you need to know about workhorse scaffolding, aiming to equip construction professionals with the insights and knowledge necessary to enhance their project outcomes.

Understanding Workhorse Scaffolding: Key Features and Benefits

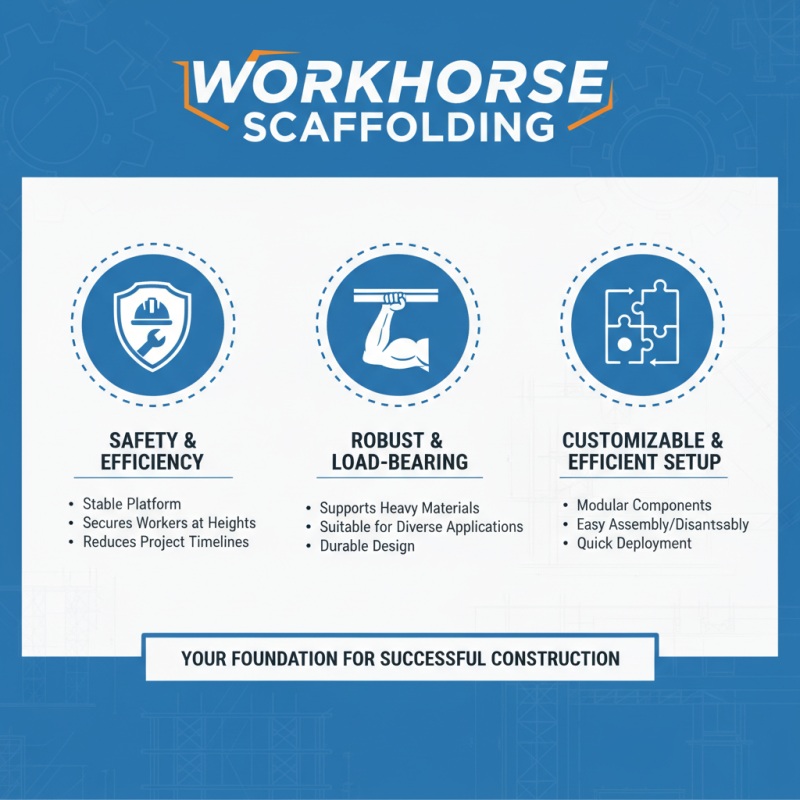

Workhorse scaffolding plays a crucial role in ensuring the safety and efficiency of construction projects. Its robust design provides a stable platform for workers, allowing them to perform tasks at various heights without compromising their safety. One key feature of workhorse scaffolding is its ability to support heavy loads, making it suitable for a wide range of applications. Additionally, the customizable nature of this scaffolding system allows for easy assembly and disassembly, facilitating quick setup times that can significantly reduce project timelines.

Tips: When selecting workhorse scaffolding for your project, consider the specific requirements of your site, including height and load capacity. Proper training for workers on how to use and inspect scaffolding systems is essential to minimize accidents. Regular maintenance checks can ensure longevity and reliability, making your investment in scaffolding worth every penny.

Furthermore, workhorse scaffolding often incorporates safety enhancements such as guardrails and non-slip surfaces. These features not only help protect workers from falls but also instill a sense of security, enabling them to focus on their tasks. The benefit of such scaffolding goes beyond safety; it boosts productivity by providing a dependable work environment where crews can move freely and efficiently.

Types of Workhorse Scaffolding: A Comprehensive Overview

When it comes to construction projects, selecting the right type of scaffolding can significantly enhance safety and efficiency. Workhorse scaffolding, known for its durability and versatility, comes in several forms tailored to meet the various demands of construction sites. The most common types include system scaffolding, tubular scaffolding, and frame scaffolding. According to a recent industry report from Research and Markets, the global scaffold market is projected to exceed $100 billion by 2025, underscoring the critical role these structures play in construction.

System scaffolding offers modular components that can be easily assembled and disassembled, making it ideal for projects requiring frequent adjustments. Tubular scaffolding is notable for its strength and reliability, suitable for high-rise builds. Meanwhile, frame scaffolding is widely used for its simplicity and fast setup time, catering to smaller jobs that don’t require extensive support. Choosing the right scaffolding type can reduce labor costs by up to 30%, by optimizing the overall workflow on-site.

Tips: Always assess the specific requirements of your project before selecting scaffolding. Consider height, load capacity, and environmental conditions to ensure maximum safety and efficiency. Furthermore, regular inspections and maintenance of scaffolding can prevent accidents, as over 4,000 injuries occur annually due to scaffolding-related incidents, according to the Occupational Safety and Health Administration (OSHA). Prioritizing safety training for workers can also enhance the efficacy of scaffolding use, fostering a culture of safety on-site.

The Ultimate Guide to Workhorse Scaffolding for Your Construction Projects

Choosing the Right Workhorse Scaffolding for Your Project Needs

When selecting the right workhorse scaffolding for your construction projects, it is vital to consider both safety and efficiency. A report from the Occupational Safety and Health Administration (OSHA) indicates that improper scaffolding practices can lead to around 4,500 injuries and 60 fatalities annually. Therefore, ensuring that the scaffolding system you choose meets safety standards is paramount. Evaluate your project requirements including height, load capacity, and the type of work being performed. This careful assessment will not only keep your team safe but also enhance productivity.

Tips: Always consider the load rating of the scaffolding you select. It's essential to choose a system that can safely support the weight of workers and materials without risk of collapse. Additionally, examine the materials used in scaffolding construction. Aluminum scaffolding, for example, is lighter and easy to transport, while steel scaffolding offers greater strength and durability for heavy-duty tasks.

Incorporating versatility into your scaffolding choice can also be beneficial. Many projects require different configurations depending on the task at hand. According to data from the National Institute for Occupational Safety and Health (NIOSH), modular scaffolding systems that can be adapted on-site can significantly reduce both setup time and the potential for errors. This adaptability allows for seamless transitions between tasks, improving overall project timelines and minimizing downtime.

Installation and Safety Guidelines for Workhorse Scaffolding

When installing Workhorse scaffolding, it is essential to adhere to strict installation guidelines to ensure safety and stability on the construction site. Begin by selecting a level base that can support the weight of the scaffolding and any loads that will be placed on it. Use proper shims to fill any gaps and ensure the scaffolding feet have a firm and stable footing. Before assembly, inspect all components for any signs of damage or wear. Adequately secure all connections using appropriate locking mechanisms to prevent accidental disassembly during use.

Safety protocols are equally crucial when working with scaffolding. Workers must be trained in proper use, including recognizing hazards associated with scaffolding work. Always wear the required personal protective equipment (PPE) such as hard hats and harnesses when working at height. Establish a clear zone around the scaffolding to keep unauthorized personnel at a safe distance. Regularly inspect the scaffolding for stability and structural integrity, especially after severe weather events. By following these installation and safety guidelines, you can create a safer work environment that minimizes the risk of accidents on the job site.

The Ultimate Guide to Workhorse Scaffolding for Your Construction Projects

| Dimension | Description | Safety Guidelines | Installation Steps |

|---|---|---|---|

| Height | Up to 30 ft. | Ensure proper bracing to prevent swaying. | 1. Set the base. 2. Install vertical frames. |

| Load Capacity | Up to 750 lbs per platform | Never exceed load limits. | 3. Attach horizontal braces. 4. Secure the platform. |

| Material | Aluminum or Steel | Check for rust or damage before use. | 5. Install guardrails. 6. Conduct a safety check. |

| Platform Size | 2 ft. x 6 ft. | Ensure platforms are secured fully. | 7. Finalize installation. 8. Keep clear of debris. |

| Access | Ladders or stairways | Use designated access points only. | 9. Train workers on access safety. |

Maintenance Tips for Long-lasting Workhorse Scaffolding Usage

Maintenance is crucial for ensuring the longevity and safety of workhorse scaffolding in construction projects. Regular inspections and upkeep can significantly extend the life of scaffolding systems, which according to industry reports, can cost upwards of $15,000 for a standard setup. Research indicates that nearly 30% of scaffolding accidents are attributed to equipment failure, highlighting the importance of proper maintenance. This not only safeguards the health and safety of workers but also mitigates potential financial losses related to downtime and equipment replacement.

One effective maintenance strategy involves routine checks of all components, including frames, planks, and connections. Inspections should focus on identifying signs of wear, corrosion, or damage that could compromise structural integrity. Data from the Occupational Safety and Health Administration (OSHA) suggests that dedicated training for personnel on maintenance protocols can reduce accidents by as much as 50%. Additionally, keeping a detailed maintenance log can help track repairs and replacements, ensuring that the scaffolding remains compliant with safety regulations and standards, ultimately leading to more efficient project timelines and reduced costs.