Essential Tips for Choosing the Right Crank Scaffold for Your Project

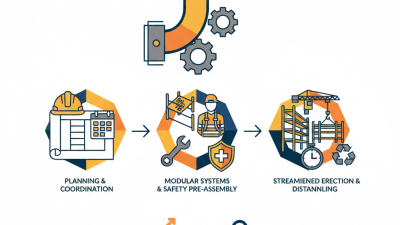

When embarking on a construction or renovation project, selecting the appropriate equipment is crucial to ensuring safety and efficiency. Among the various types of scaffolding available, crank scaffold stands out as a versatile option that can adapt to different heights and site conditions. With its adjustable features, crank scaffold not only provides reliable support for workers but also facilitates smooth access to elevated areas, improving workflow and productivity. However, choosing the right crank scaffold for your specific project requires careful consideration of various factors.

This guide aims to equip you with essential tips for selecting the most suitable crank scaffold to meet your needs. From understanding load capacities and height adjustments to assessing the material quality and safety standards, making an informed choice is vital. By following these insights, you can ensure that your crank scaffold not only enhances the overall efficiency of your project but also prioritizes the safety of all personnel involved. Whether you're a seasoned contractor or a DIY enthusiast, understanding these key aspects will help you navigate the options available and select the right crank scaffold with confidence.

Understanding the Basics of Crank Scaffolds and Their Applications

Crank scaffolds are essential tools in the construction and maintenance industries, designed to provide safe and versatile support for a variety of projects. Understanding the basics of crank scaffolds involves recognizing their significant components, which primarily include the platform, adjustable crank mechanisms, and sturdy frames. These features allow for height adjustments, making them adaptable for tasks ranging from painting high walls to installing windows. Importantly, they provide a stable working surface, safeguarding workers while they perform tasks at elevated levels.

Applications of crank scaffolds extend beyond mere construction; they are invaluable in repair and renovation scenarios as well. For instance, in historical buildings where precision is crucial, crank scaffolds can be adjusted to fit the unique contours of the structure. Similarly, in industrial settings, these scaffolds support maintenance tasks that require elevated access to machinery or infrastructure. Their versatility makes them suitable for both indoor and outdoor use, providing a reliable solution for workers to safely reach necessary heights while ensuring efficiency in project execution. Understanding these baselines can aid project managers and contractors in selecting the right scaffolding solution tailored to their specific needs.

Essential Tips for Choosing the Right Crank Scaffold for Your Project

| Feature | Description | Application | Weight Capacity | Height Adjustment |

|---|---|---|---|---|

| Material | Aluminum or Steel | Construction, Maintenance | Up to 2000 lbs | Adjustable up to 10 feet |

| Base Width | Narrow or Wide options | Residential, Commercial | Varies with design | Fixed height |

| Mobility | Wheeled or Stationary | Events, Renovations | Up to 1500 lbs | Fixed height |

| Assembly | Easy or Complex | DIY Projects | Depends on setup | Manual adjustment |

| Safety Features | Guardrails, Stabilizers | High-Risk Jobs | Standard compliance | Variable |

Key Considerations for Selecting the Right Crank Scaffold for Your Needs

When selecting a crank scaffold for your project, several critical factors must be considered to ensure safety and efficiency. First, assess the height and reach requirements specific to your task. A crank scaffold allows for height adjustments, but it’s essential to choose one that meets the maximum elevation needed for your project. Taller options may be necessary for high-ceiling work, whereas standard models might suffice for more routine tasks. Additionally, evaluate the load capacity of the scaffold; understanding the weight of your materials and equipment is vital to prevent overloading and potential accidents.

Another important aspect is the workspace and site conditions. Consider the surface on which the scaffold will be placed; it should be stable and level to ensure safe usage. If the project site includes uneven terrain, adjustable feet or leveling capabilities will be advantageous. Also, think about the accessibility of the scaffold, taking into account whether it will fit through doorways or narrow paths while being transported. Finally, ensure that the design allows for easy assembly and disassembly, as this will contribute to a more efficient workflow and minimize downtime on the project.

Evaluating Load Capacity and Safety Standards in Scaffold Selection

When selecting a crank scaffold for your project, evaluating load capacity is a crucial step to ensure safety and efficiency. Load capacity refers to the maximum weight a scaffold can support, which includes the weight of materials, tools, and personnel. It is essential to review the manufacturer's guidelines and specifications to determine the appropriate load limits for your specific scaffold type. Selecting a scaffold with an adequate load capacity not only helps prevent accidents but also ensures compliance with safety regulations.

In addition to load capacity, adhering to safety standards is paramount in scaffold selection. Various organizations provide safety guidelines that dictate the necessary conditions for scaffold construction and usage. Factors such as height restrictions, platform width, and structural integrity should be carefully assessed. Furthermore, regular inspections and maintenance can help identify any wear and tear, ensuring that the scaffold remains safe to use throughout the project. By prioritizing these elements, you can create a safe working environment and minimize the risk of injuries related to scaffold operations.

Comparing Different Types of Crank Scaffolds and Their Features

When selecting the right crank scaffold for your project, it's essential to understand the various types available and their unique features.

One common type is the adjustable crank scaffold, which allows for quick height adjustments to accommodate uneven surfaces and different working heights. This flexibility is particularly valuable in construction sites where ground conditions may vary dramatically, ensuring that workers can access their tasks safely and efficiently.

Another popular option is the rolling crank scaffold, designed for mobility. This type is equipped with wheels, enabling it to be easily maneuvered across different sections of a site without requiring disassembly. It's ideal for projects that need frequent repositioning, reducing downtime and improving workflow. Additionally, the portability of rolling scaffolds enhances safety by minimizing the need for workers to carry heavy tools and materials over long distances.

Tips for choosing the right model include assessing the height and reach required for your project and considering the load capacity necessary for your team and equipment. Also, don’t overlook safety features; look for scaffolds with secure locking mechanisms and sturdy materials that can withstand the rigors of your work environment. Finally, consider ease of assembly and disassembly, as a scaffold that can be set up quickly can save time and resources.

Maintenance and Care Tips for Ensuring Long-term Scaffold Performance

Proper maintenance and care of a crank scaffold are critical for ensuring its longevity and safety during use. Regular inspections should be conducted to identify any signs of wear and tear. This includes checking for rust or corrosion on metal components, ensuring that all locking mechanisms are functioning correctly, and assessing the integrity of the platform. Any damaged parts should be repaired or replaced promptly to avoid accidents and maintain structural stability.

Additionally, it is important to clean the scaffold regularly to prevent dirt and debris accumulation, which can lead to deterioration. Depending on the environment in which the scaffold is used, different cleaning solutions may be more appropriate. Always follow up with a thorough drying process to prevent moisture-related issues. Lastly, when the scaffold is not in use, store it in a dry, safe location, preferably indoors. This practice will protect it from harsh weather conditions and extend its operational life, ensuring that it remains safe and reliable for future projects.

Related Posts

-

Discover the Best Crank Up Scaffolding for Sale: Top Models of 2025

-

How to Effectively Use Non Stop Crank Up Scaffolding for Your Construction Projects

-

Why You Should Consider Buying EZ Scaffold for Sale Today

-

How to Crank Up Scaffolding for Your Construction Projects Efficiently

-

Discover Affordable Non Stop Scaffolding for Sale: Buy Now for Your Project!

-

Top 10 Tips for Finding Quality Used Non Stop Scaffolding for Sale