Non Stop Crank Up Scaffolding Tips for Efficient Construction Projects?

In the bustling world of construction, efficiency is paramount. Notably, "non stop crank up scaffolding" has emerged as a game-changer in this arena. Industry expert John Smith emphasizes, "The key to reducing downtime is effective scaffolding solutions." This speaks volumes about the need to optimize construction processes.

Using non stop crank up scaffolding allows crews to work seamlessly at various heights. With this innovative system, workers can quickly adjust scaffolding as their tasks progress. However, challenges remain. Ensuring safety while maintaining speed can sometimes create a delicate balance. Inadequate training on these systems can lead to inefficiencies and accidents.

Moreover, it's essential to regularly assess equipment and operational procedures. Overlooking these factors can turn a seemingly smooth project into a chaotic endeavor. By refining our approach to non stop crank up scaffolding, we can strive for a more efficient and safer construction environment. Learning from past mistakes will ultimately pave the way for improved practices in the industry.

Effective Planning for Scaffolding in Construction Projects

Effective planning for scaffolding in construction projects is crucial. A well-thought-out scaffold plan ensures safety and efficiency on site. Poor planning can lead to delays and accidents. Assessing the site thoroughly before setting up is essential. Know the layout, access points, and potential hazards.

Tips for scaffolding include creating a detailed design. It should match the specific tasks ahead. Keep communication clear among team members. Everyone needs to understand their role. Regular safety checks are critical. They help identify risks before they escalate.

Ensure materials are readily available. This saves time and keeps the project on track. Having a contingency plan for weather changes can be beneficial. Unexpected rain or wind can delay work. Be ready to adapt and rethink strategies. Flexibility in planning can save a project.

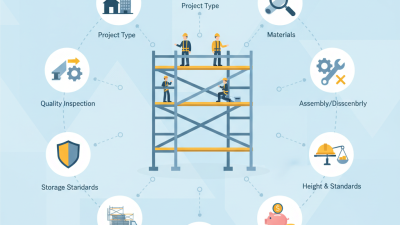

Choosing the Right Type of Scaffolding for Your Needs

When it comes to scaffolding, the choices can be overwhelming. It’s crucial to select the right type. Different projects have unique requirements, and the correct scaffolding can make a difference. Evaluate your project size. For smaller jobs, mobile scaffolding might be sufficient. Larger projects may need complex systems like frame scaffolding.

Consider the type of work being done. Are you painting, cleaning, or installing? Each task may require different scaffolding setups. Safety should always be a priority. Regularly inspect your scaffolding for damages or wear. Make sure it's set up on stable ground.

Here are some tips for effective scaffolding:

- Always communicate with your team about setup plans.

- Set clear guidelines for safe usage.

- Provide training to all staff.

Best Practices for Scaffolding Assembly and Disassembly

Scaffolding plays a crucial role in construction projects. However, improper assembly and disassembly can lead to delays and accidents. Following best practices is essential for efficiency.

Begin by inspecting all scaffolding components. Look for cracks or rust. This can prevent larger issues later. Assembly should follow a clear plan. Position base plates on firm ground. Level the scaffold before adding more sections.

When it comes to disassembly, do it methodically. Start from the top and work downward. Ensure that all workers are clear of the scaffolding. Leaving tools and materials behind can create hazards. Take the time to double-check your work. Missing a step can lead to serious accidents.

Non Stop Crank Up Scaffolding Tips for Efficient Construction Projects

| Tip No. | Scaffolding Tip | Description | Best Practices |

|---|---|---|---|

| 1 | Thorough Planning | Plan the layout and design before assembly. | Conduct site assessments and feasibility studies. |

| 2 | Material Quality | Use high-quality scaffolding materials. | Regularly inspect materials for damage or wear. |

| 3 | Proper Assembly Techniques | Follow strict assembly guidelines. | Ensure all connections are tight and secure. |

| 4 | Regular Maintenance | Perform routine maintenance checks. | Address any issues immediately to prevent accidents. |

| 5 | Safety Protocols | Enforce safety regulations and training. | Conduct safety drills and provide gear for all workers. |

Safety Measures for Scaffolding Operations on Construction Sites

When using scaffolding on construction sites, safety is paramount. Workers often face risks from falls and unstable structures. It's crucial to assess the site before setting up scaffolding. Check the ground conditions for stability. Poor ground can lead to accidents.

Proper training for workers is essential. They must understand how to use scaffolding safely. Regular safety drills can keep everyone alert. Just a moment of distraction can result in serious injuries. Also, inspect the scaffolding regularly. Look for any signs of wear or damage. Small issues can escalate if not addressed quickly.

Personal protective equipment is a must. Harnesses and helmets can save lives. Yet, some workers might disregard these rules. Habitual negligence makes them vulnerable. A culture of safety has to be cultivated. Open discussions about risks can help in creating awareness. Each individual’s responsibility is to prioritize safety.

Scaffolding Safety Measures on Construction Sites

Maintenance and Inspection Tips for Long-lasting Scaffolding Solutions

When it comes to scaffolding, maintenance and inspection are crucial. Regular checks can prevent accidents and prolong service life. Inspect joints, bolts, and planks frequently. Look for rust, cracks, or wear. These issues can weaken the structure and lead to failures.

Cleaning is often overlooked but essential. Remove dirt and debris to avoid corrosion. It’s easy to forget this step. A clean scaffold maintains its integrity longer. Ensure it is stored properly when not in use. Exposure to harsh weather can cause damage over time.

Proper training for workers is vital. They need to understand safety protocols. Misuse can lead to unnecessary risks. Encourage open communication about concerns. Reflect on past issues to improve future practices. Regular reviews can help identify areas needing attention.

Related Posts

-

How to Effectively Use Non Stop Crank Up Scaffolding for Your Construction Projects

-

Why You Should Crank Up Scaffolding for Your Construction Project Success

-

What is EZ Scaffolding and How Does It Benefit Construction Projects

-

10 Essential Tips for Choosing the Right Workhorse Scaffolding?

-

Essential Tips for Choosing the Right Crank Scaffold for Your Project

-

Why Crank Up Scaffolding is Essential for Safe Construction Practices?