10 Essential Tips for Choosing the Right Workhorse Scaffolding?

Choosing the right workhorse scaffolding can be a daunting task. With countless options available, making an informed decision is crucial. Workhorse scaffolding plays a vital role in construction and maintenance projects. It provides the necessary support and safety, especially for those working at heights.

Consider the project type before making a choice. From residential renovations to large commercial buildings, each project may require different scaffolding features. Pay attention to the materials used in the scaffolding. Steel and aluminum each have their own benefits and drawbacks, affecting weight and durability.

Quality matters. Inspect the scaffolding thoroughly before renting or purchasing. Even small defects can pose serious risks. Always consider ease of assembly and disassembly. A cumbersome setup can lead to frustration and wasted time. Lastly, think about storage and transport. The right workhorse scaffolding should be practical, fitting your space and logistics. Keep these tips in mind for a successful choice.

Factors to Consider When Selecting Workhorse Scaffolding Materials

Choosing the right workhorse scaffolding materials requires careful consideration. The weight capacity is crucial. If the scaffolding cannot support the load, it poses safety risks. Ensure the materials can handle the expected weight, plus some extra as a safety margin.

Durability also plays a key role. Consider weather resistances such as rust and corrosion. Scaffolding exposed to the elements must withstand these challenges. It’s advisable to use materials designed for the specific environmental conditions. However, finding a balance can be tricky. Higher-quality materials often mean higher costs. Sometimes, budget constraints lead to suboptimal choices. This can result in higher costs later due to repairs or replacements.

Safety features should not be overlooked. Look for guardrails and toe boards to prevent falls. But also focus on how easy the scaffolding is to assemble and disassemble. Complicated setups can lead to mistakes, which may cause accidents. It’s essential to regularly inspect the equipment to ensure ongoing safety. Reflections on previous experiences can provide valuable lessons for future projects.

Workhorse Scaffolding Material Selection Factors

Understanding Load Capacity Requirements for Effective Scaffolding Use

When selecting scaffolding, understanding load capacity is crucial. Each scaffolding component has a specific load limit. Overloading can lead to accidents. Always check load charts and specifications. Misjudging weight can have severe consequences. Make sure to account for materials, tools, and workers on the scaffolding.

Tip: Assess your project needs carefully. Consider the weight of all materials that will be on the scaffolding. This includes safety equipment. Also, think about the maximum number of workers that might be present. It’s easy to overlook smaller items that can add up quickly.

Another important aspect is testing and maintenance. Regularly inspect your scaffolding. Look for signs of wear or damage. If it fails to meet safety standards, it becomes a risk. Don't ignore these checks. Make it a habit.

Tip: Involve experienced personnel in your decision-making. Seek their advice on load capacities. Their insights can help prevent costly mistakes. Always prioritize safety when selecting scaffolding options. A well-chosen structure enhances productivity and ensures worker safety.

Evaluating Scaffolding Design: Stability and Safety Standards Compliance

When choosing workhorse scaffolding, stability and safety are paramount. A well-designed scaffold must withstand various loads. Inspect the connections and joints. They should be tight and sturdy. Any play at these points could lead to a collapse. Use scaffolding that meets established safety standards. Compliance with local regulations is crucial. It ensures that the structure is safe for all users.

Consider the materials used in the scaffolding. Steel and aluminum are common choices. Steel provides strength, while aluminum is lightweight. Each option has its pros and cons. Reflect on the specific job requirements. Will the scaffolding be exposed to harsh weather? Choose materials accordingly. Safety features are just as important. Look for guardrails and toe boards. These additions can prevent accidents and fall-related injuries.

Evaluate the design's stability. A wider base can enhance safety but may take up more ground space. Reflect on the terrain where it will be used. Uneven ground can compromise stability. Disposable platforms might offer quick solutions but often lack durability. Think carefully about the long-term implications of your choice. Safe scaffolding isn't just about selecting an option. It's about ongoing reflection and assessment during the job. Prioritize safety for yourself and the team.

10 Essential Tips for Choosing the Right Workhorse Scaffolding

| Tip No. | Tip Description | Stability Factors | Safety Standards Compliance |

|---|---|---|---|

| 1 | Select scaffolding suitable for your specific job requirements. | Check load capacity and base width. | Complies with OSHA regulations. |

| 2 | Assess materials used in the scaffolding. | Material strength and durability. | Meets ASTM standards. |

| 3 | Ensure proper design and engineering analysis. | Consider height and configuration. | Verified by engineering certification. |

| 4 | Check for base plates and mud sills to prevent sinking. | Properly leveled and secured. | Follows site safety plans. |

| 5 | Employ guardrails and toe boards for worker safety. | Prevent falls and dropped tools. | Adheres to safety codes. |

| 6 | Choose appropriate scaffolding type according to task. | Evaluate modular versus frame scaffolding. | Conforms to local regulations. |

| 7 | Train workers on scaffolding safety and usage. | Knowledge of scaffold operation. | Regular safety audits. |

| 8 | Inspect scaffolding before each use. | Check connections and joints. | Inspected by qualified personnel. |

| 9 | Ensure adequate access and egress from scaffolding. | Avoid overcrowding on scaffolds. | Follows evacuation plans. |

| 10 | Consider weather conditions and site variables. | Secure scaffolding in high winds. | Adapts to environmental conditions. |

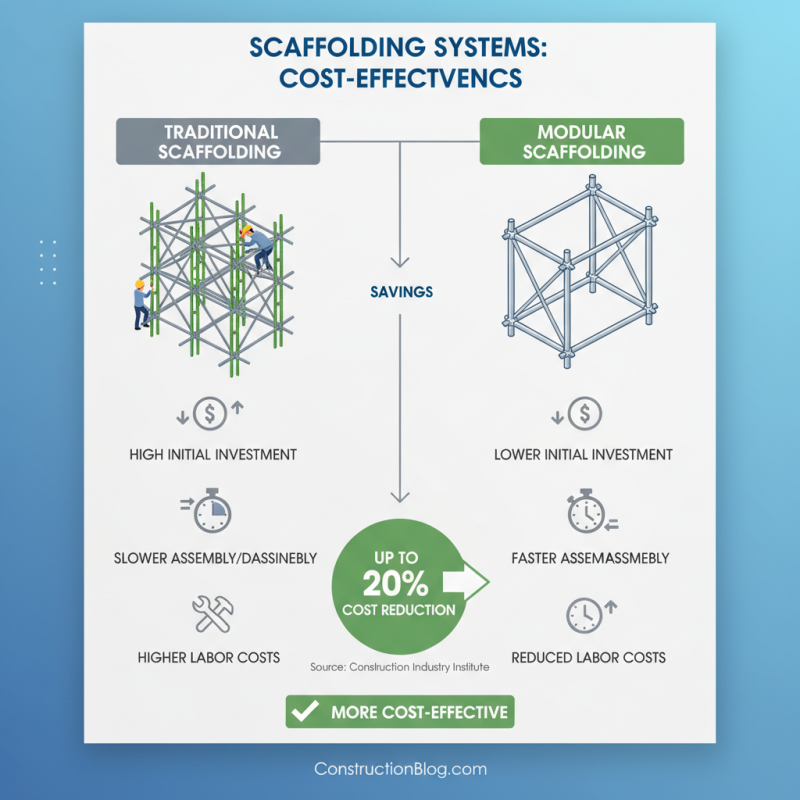

Comparing Cost-Effectiveness of Different Scaffolding Systems

When comparing the cost-effectiveness of different scaffolding systems, there are several factors to consider. The initial investment is crucial. According to a report by the Construction Industry Institute, modular scaffolding can reduce costs by up to 20% compared to traditional systems. This is largely due to faster assembly and disassembly, saving on labor costs.

However, the long-term sustainability of scaffolding options should not be overlooked. Pole scaffolding may be cheaper upfront but often requires more maintenance. A study from the American Society of Civil Engineers indicates that lack of proper upkeep can increase overall expenses by 15% over time.

Moreover, the adaptability of scaffolding systems plays an important role. For instance, adjustable systems allow for flexibility on varying job sites. Yet, this might come with a higher price tag. Evaluating the return on investment is essential but challenging, as it involves estimating potential downtime. These reflections remind us that making a choice isn’t just about the numbers.

Assessing the Importance of Mobility and Assembly Efficiency in Scaffolding

When assessing scaffolding, mobility is crucial. A workhorse scaffold must be easily movable. This allows quick repositioning during a project. Workers can shift it without hassle. A scaffold that isn’t mobile can slow down progress, causing frustration. Imagine a project where the scaffold is stuck in one place. It becomes a big issue, delaying tasks and wasting time.

Efficiency in assembly is equally important. Scaffolding should be easy to set up and dismantle. Complicated designs can lead to errors. Speed is often critical on job sites. A scaffold that takes too long to assemble can hinder productivity. Workers may rush, leading to potential safety risks. It's important to find the balance between speed and safety.

Not all scaffolds meet these criteria. Some may seem appealing at first glance. However, a closer inspection often reveals flaws. Weak points, poor mobility, and difficult assembly can become problematic. Evaluating these factors before purchasing is essential. Ignoring them could lead to unnecessary complications later on. Every detail matters in ensuring a successful scaffolding experience.

Related Posts

-

How to Effectively Use Non Stop Crank Up Scaffolding for Your Construction Projects

-

What is Crank Scaffold and How is it Used in Construction?

-

The Ultimate Guide to Workhorse Scaffolding for Your Construction Projects

-

Essential Tips for Choosing the Right Crank Scaffold for Your Project

-

Why You Should Crank Up Scaffolding for Your Construction Project Success

-

How to Find the Best EZ Scaffold for Sale Online?