Why Crank Up Scaffolding is Essential for Safe Construction Practices?

In the construction industry, safety is paramount, and the implementation of robust scaffolding systems plays a crucial role in maintaining a secure work environment. One effective solution that has garnered attention is crank up scaffolding, a versatile and adjustable framework that allows workers to easily access elevated areas while ensuring stability. This type of scaffolding significantly enhances safety measures on construction sites by providing a reliable platform that can be modified to suit various project requirements.

Crank up scaffolding not only offers ease of use but also facilitates quick adjustments in height, making it an ideal choice for projects that demand flexibility and efficiency. As construction practices evolve, the adoption of such innovative systems becomes increasingly vital in preventing accidents and injuries. By prioritizing safety through the use of crank up scaffolding, construction companies can create safer working conditions, fostering a culture of responsibility and care for the well-being of their workforce. This introduction will explore the significance of crank up scaffolding in promoting safe construction practices and its impact on the overall industry.

The Importance of Scaffolding in Construction Safety Standards

Scaffolding plays a pivotal role in maintaining safety standards on construction sites. It serves as a temporary structure that provides workers with access to various heights while ensuring their stability and security. When properly installed and maintained, scaffolding can significantly reduce the risk of falls, which are among the leading causes of injuries in the construction industry. This makes it essential for compliance with safety regulations that govern construction practices.

Moreover, the importance of scaffolding extends beyond worker safety; it also contributes to the efficiency of the construction process. With secure scaffolding in place, workers can perform their tasks more effectively, minimizing delays caused by safety concerns or accidents. Additionally, proper scaffolding design can accommodate various materials and tools, further enhancing productivity. By integrating scaffold systems into construction protocols, companies can foster a culture of safety and efficiency, ultimately leading to better project outcomes and fewer work-related incidents.

Importance of Scaffolding in Construction Safety Standards

This chart illustrates the significance of various scaffolding safety practices based on survey responses from construction professionals. The data highlights the areas where scaffolding is most critical for ensuring worker safety on construction sites.

Key Benefits of Using Crank Up Scaffolding for Workers’ Safety

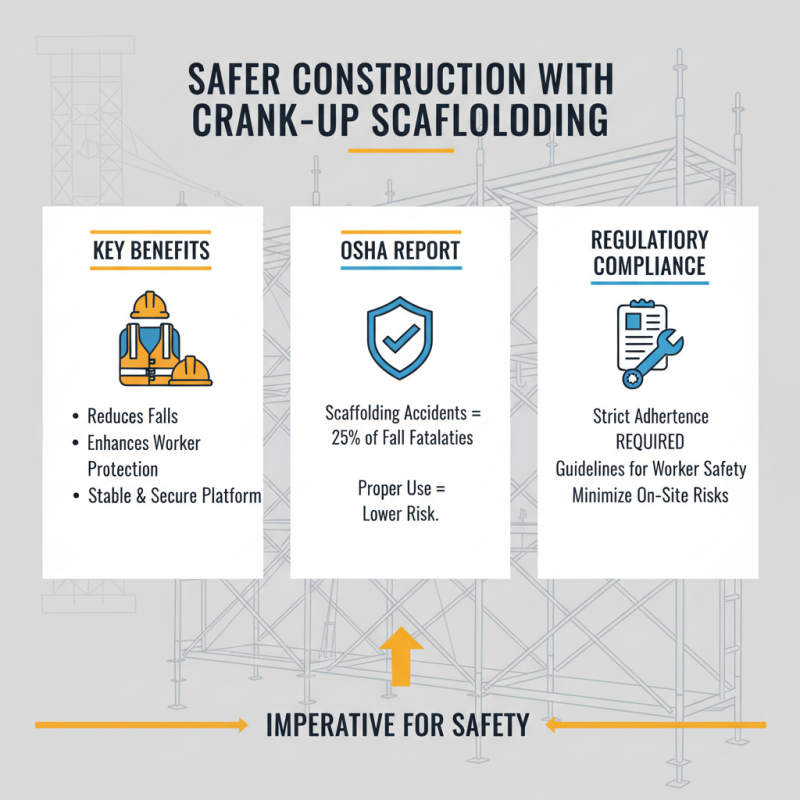

Crank up scaffolding is a pivotal element in ensuring worker safety on construction sites. According to a report from the Occupational Safety and Health Administration (OSHA), falls are the leading cause of fatalities in the construction industry, accounting for approximately 33% of all deaths. Implementing crank up scaffolding significantly mitigates this risk by providing workers with a stable and adjustable platform elevated to the necessary height. This adjustability not only enhances the workers' ability to perform tasks at varied heights but also allows for swift modifications in response to project requirements, ultimately fostering a safer environment.

Moreover, crank up scaffolding is designed with safety features that reinforce its reliability. For instance, studies show that scaffolding equipped with guardrails can reduce the risk of falls by up to 80%. This type of scaffolding supports a safe working posture, decreasing the likelihood of accidents caused by overreaching or unstable surfaces. Additionally, the ease of assembly and disassembly of crank up scaffolding allows for regular inspections and maintenance, ensuring that workers are always using equipment that meets strict safety standards. By prioritizing the use of crank up scaffolding, construction sites can make significant strides toward achieving a safer work environment, ultimately lowering injury rates and enhancing overall productivity.

Why Crank Up Scaffolding is Essential for Safe Construction Practices? - Key Benefits of Using Crank Up Scaffolding for Workers’ Safety

| Benefit | Description | Impact on Safety |

|---|---|---|

| Adjustable Height | Allows for easy modification of the scaffold height to match the needs of the task. | Prevents falls and injuries by ensuring workers can reach their work areas safely. |

| Increased Stability | Offers a robust framework that maintains steadiness during use. | Reduces risk of collapses or slips, enhancing overall site safety. |

| Ease of Access | Design allows workers to easily access various heights without cumbersome ladders. | Minimizes the chances of falls by providing safer access options. |

| Quick Assembly | Facilitates fast setup and teardown, allowing for efficient project timelines. | Less time spent on setup reduces the exposure of workers to potential hazards. |

| Versatile Configuration | Can be configured in various ways to suit different tasks and types of work environments. | Enhances adaptability to various job sites, promoting safety by fitting specific conditions. |

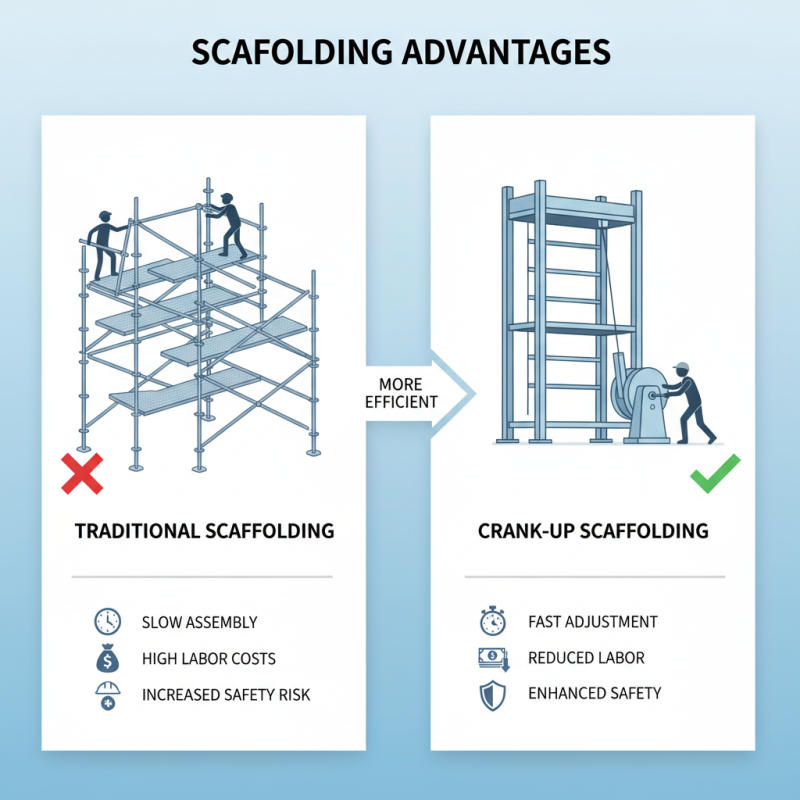

Comparing Crank Up Scaffolding with Traditional Scaffolding Types

Crank up scaffolding offers significant advantages over traditional scaffolding types, primarily due to its unique design and functionality. Traditional scaffolding, such as tube and coupler or frame systems, often requires extensive manual labor to assemble and adjust to the desired height. This can lead to increased time on-site, higher labor costs, and a greater risk of accidents during setup. In contrast, crank up scaffolding features a vertical adjustment mechanism that facilitates quick elevation and lowering with minimal effort. This efficiency reduces the number of workers needed for assembly, contributing to a safer working environment.

Moreover, crank up scaffolding is designed to provide enhanced stability and support. Unlike traditional scaffolding, which may require several diagonal bracings to ensure its strength, crank up systems often incorporate integrated features that optimize load distribution. This ensures that the structure remains solid even when under significant weight or during high winds. Additionally, the ability to quickly adjust the height helps maintain the right working conditions for various tasks, whether in construction or maintenance, thus promoting safety and efficiency in operations. The advances in crank up scaffolding technology demonstrate its role as a valuable alternative for construction practices, emphasizing the need for continuous innovation in ensuring worker safety and operational efficiency.

Regulatory Guidelines for Crank Up Scaffolding Usage in Construction

Crank up scaffolding plays a significant role in ensuring safe construction practices, and its usage is subject to various regulatory guidelines designed to protect workers on site. According to a report from the Occupational Safety and Health Administration (OSHA), proper scaffolding can reduce the likelihood of falls—one of the leading causes of fatalities in the construction industry. In fact, scaffolding accidents account for about 25% of these fall-related deaths. Therefore, strict adherence to regulatory guidelines is imperative to minimize risks and enhance worker safety.

Regulatory guidelines for crank up scaffolding include compliance with load capacity, stability, and proper assembly techniques. The American National Standards Institute (ANSI) emphasizes that all scaffolding systems must support at least four times the intended load without failure. Additionally, workers must be properly trained in scaffold erection, inspection, and dismantling, ensuring they understand the specific requirements tailored to crank up scaffolding. Studies have shown that construction sites adhering to these regulations not only experience fewer accidents but also improve overall project efficiency, leading to significant long-term economic benefits. Compliance not only fosters a safer work environment but also promotes a culture of safety that is crucial in the high-risk construction industry.

Common Hazards and Best Practices for Scaffolding Safety Management

Scaffolding is an integral part of the construction industry, providing critical support for workers and materials. However, it also presents various hazards that need effective management. According to the U.S. Occupational Safety and Health Administration (OSHA), approximately 65% of construction workers regularly work on scaffolds, making them susceptible to serious injuries, including falls, which account for over 30% of construction-related fatalities. Identifying common hazards is the first step in promoting scaffolding safety. These hazards include structural integrity failures, falls from heights, and improper use of scaffolding equipment.

Best practices in scaffolding safety management emphasize thorough training and regular inspections. Workers should undergo comprehensive training that covers not just the proper setup and dismantling of scaffolds but also fall protection techniques. Additionally, scaffolding should be inspected daily to ensure it is structurally sound and free from defects. A report by the International Safety and Health Association (ISHA) highlights that consistent adherence to these practices can reduce scaffolding-related accidents by up to 50%. Establishing a culture of safety where team members can report unsafe conditions without fear, coupled with constant monitoring, furthers the protection of all personnel on-site. By prioritizing scaffolding safety management, construction firms can significantly mitigate risks and enhance workforce protection.

Related Posts

-

Discover the Best Crank Up Scaffolding for Sale: Top Models of 2025

-

Top 10 Best EZ Scaffolds for Sale: Affordable Options for Every Project

-

The Ultimate Guide to Workhorse Scaffolding for Your Construction Projects

-

How to Crank Up Scaffolding for Your Construction Projects Efficiently

-

Top 10 Tips for Finding Quality Used Non Stop Scaffolding for Sale

-

Why You Should Consider Buying EZ Scaffold for Sale Today